Phase Change Materials

Mechanical cooling and heating should never be used as a substitute for good design

At CoolairAustralia, our Sales Engineers’ performance is not measured as to how many units or products have been sold to customers, their performance is measured as to how much energy is saved from day to day operation of our proposed solution.

At CoolairAustralia, our starting point is always to look at natural systems and design a building which uses passive solutions (optimal daylight, harvest the sun, provide shade by natural elements, etc.) and only use technical M&E solutions if required; that is why PCM is of key essence in our passive solar building design methodology.

Sustainable and cost effective, PCM materials provides an effective and simple approach for integrating smart phase change materials into buildings and HVAC products to ensure the maximum save energy result alongside with our AWARD Winning save energy products.

CoolairAustralia’s PCM products absorb and releases heat using bio-based phase change materials that melt and solidify at room temperature. Unlike other PCM products derived from petroleum or salt hydrates, Coolair’s PCM is derived from abundant bio-based materials. When installed in ceiling and wall panels the product works day and night to stabilize indoor temperatures. This simple passive approach to saving energy provides greater comfort for building occupants and more efficient HVAC system

What is PCM?

Phase Change Materials (PCMs) are products that store and release thermal Energy during the process of melting & freezing (changing from one phase to Another). When such a material freezes, it releases large amounts of energy In the form of latent heat of fusion, or energy of crystallization. Conversely, When the material is melted, an equal amount of energy is absorbed from the immediate environment as it changes from solid to liquid.

How it Works?

Phase Change Energy Storage is the temporary storage of high or low temperature energy for later use. It bridges the gap between energy requirement and energy use. A thermal storage application may involve a 24 hour or alternatively a weekly or seasonal storage cycle depending on the system design requirements. Whilst the output is always thermal, the input energy may be either thermal or electricity.

For the majority of applications, PCM solutions have to be encapsulated in sealed containers. To this end, CoolairAustralia. have developed many different standard type containers as well as custom-made containers for special applications. These containers can be applied to any water or air based PCM systems and can be manufactured using our patented earth friendly Phase Change Materials (PCM) solutions which have operating temperatures between -40ºC (-40ºF) and +117 ºC (+273 ºF)

In the example below, you can see a quick explanation of how our products perform. In the first image we see what happens in the day with discharge period and what happens in the night with the charge period.

Ceiling Application Of PCM

Placing Coolair’s PCM carpet into the ceiling cavity, on-top of ceiling tiles is one of the easiest, most cost effective applications of Coolair’s PCM mat possible.

Unlike insulation, where you are creating a barrier to resist thermal change, phase change materials ideally only need to cover around 70% of the area. This allows for rapid installation that can be performed by the building occupants or facility maintenance technicians.

Ideal for spaces that have significant internal loads from people, lights and equipment and have discomfort issues.

In new and retrofit Coolair’s PCM mat ceiling tile installations we consistently see significant savings on HVAC energy and maintenance expenditures while enhancing occupant comfort. Moreoved if additionally matched with our Award Winning save energy cooling/heating or ventilation systems can slash near to zero the energy consumed for cooling & heating.

Stud Walls Application Of PCM

In new construction the most common means of installation is to secure Coolair’s PCM mat in between the studs of the wall between the insulation and the wallboard.

Recommended Coolair’s PCM mat M values per orientation (Northern Hemisphere) :

South C51A (or C91A in extreme climates)

West C51A

East C27A

North – A 27 (or No PCM in moderate climates)

These recommendations are based on modeling and first principal physics of the effects of Solar radiation on building envelopes. For spaces with large internal gains, north orientations may be useful, however north orientations are recommended only when other orientations are not available. Coolair’s PCM wall applications are generally specified after Coolair’s PCM roof applications because roof applications tend to provide greater benefits.

Coolair’s PCM goes beyond insulation by providing thermal energy storage at the source of the load, greatly reducing wall heat flux and energy consumption.

Shifting daytime solar loads to nighttime allows your building to recycle energy. This cycling of thermal energy reduces HVAC system run-time, maintenance, system size and energy consumption while enhancing human comfort.

HVAC Application Of PCM

Coolair’s PCM solutions have been applied for heat pipe passive cooling units as a direct air cooling applications. Coolair’s PCM solutions are also successfully applied for passive cooling applications such as chilled ceiling / cooling tower free cooling circuits as well as heat

Rejection systems.

In the examples below, you can see a quick visual explanation of how our products perform for near to zero energy used for Passive cooling. In the first image we see a ceiling fan to provide aircondition quality air in the day with over 90with discharge period and what happens in the night with the charge period.

Zero Net Energy Application Of PCM

Coolair’s PCM solutions based energy storage unit is utilized to work together with our solar energy systems and our geothermal or air source heat pumps to provide for off-grid or on-grid houses over 70% or 100% full energy saved.External or underground space is provided for Coolair’s PCM solutions unit. Heat is transferred to inner house by hot wind or by warm water pipe that’s equipped under in the floor.In the example below, you can see a quick visual explanation of how our products perform for near to zero energy used for passive cooling / heating.1. Solar panels covering the whole roof, while transferring solar energy to electricity energy, extra heat will be produced. Extra heat is transferred by heat pump powered by air blower. Independent and included basement is full with dozens of PCM based heat storage units.

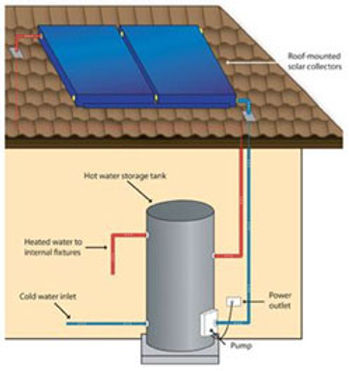

Boiler Hot water Application Of PCM

Solar-Thermal energy is generally stored in the form of heated water (sensible heat). Due to time-dependent and unpredictable characteristics of sun exposure, the efficiency of solar-thermal systems relies on the efficiency of thermal energy storage technology.

Solar-Thermal energy can be stored in the form of latent heat by using a suitable Phase Change Material (PCM). This offers a higher heat storage capacity per volume/mass and a higher temperature stability of stored hot water.

Utilization of solar-thermal energy storage tanks with PCM based latent heat storage technology is expected to enhance the efficiency of available solar-thermal systems. The higher efficiency is achieved by bridging the gap between solar heat availability and hot water demand.

Phase change material (PCM) absorbs heat during its phase change cycle from solid to liquid during the daytime solar cycle. The amount of heat that a tank of water can absorb is much higher with the presence of phase change material. Our PCM is a non-toxic & non-flammable, inorganic PCM, that can be encapsulated in 50-100mm polypropylene or high density polyethylene balls. They are then added to insulated, atmospheric water storage tanks. This PCM operates from 52 degrees C to 63 degrees C (126 degrees F to 145 degrees F) with a phase change temperature of 55 degrees C to 59 degrees C (131 degrees F to 138 degrees F). This latent heat stored in PCM maintains the temperature of stored water for longer periods and also pre-heats cold inlet water during the absence of solar heat. Latent heat storage technology also reduces water temperature fluctuations in solar thermal system as PCM stabilizes temperatures.